Good quality Belt Chip Conveyor – Magnetic Type Chip Conveyor Equipment – JINAO

Good quality Belt Chip Conveyor – Magnetic Type Chip Conveyor Equipment – JINAO Detail:

Magnetic chip conveyor utilizes the strong magnetic effect generated by the permanent magnet material to separate the powdery, granular and iron chips having a length of less than 100 mm, the debris in the cooling medium, and adsorbed on the working surface of the chip discharging machine. Delivered to the designated station. The machine can be widely used in CNC machining machines, combined machine tools, machining centers and other mechanical processing equipment and production lines for iron filings, and can be used for dry and warm processing of iron filings.

The device adopts a closed structure, uniform chip discharge, stable operation, low noise, and can be used for transportation and lifting of iron parts, and can be used as a primary filter in combination with a purifying device.

The Main Technical Parameters

| Style | Working width B | B1 | B2 | H(m) | H1 | H2 | H3/L1 | L(m) | a | kg/h | kw | l/min |

| SHYC150 | 150 | 220 | ≥300 | 0-3 | 130 175 204 | H1+≥30 (hypotenuse) | User-defined | 0.6-10 | 100 | 0.2-0.75 | 25 | |

| SHYC200 | 200 | 270 | ≥350 | 0-5 | 130 175 204 | 0.6-30 | 0° | 150 | 0.2-1.5 | 50 | ||

| SHYC250 | 250 | 320 | ≥400 | 0-10 | 130 175 204 | 30° | 200 | 0.2-1.5 | 100 | |||

| SHYC320 | 320 | 390 | ≥500 | 0-10 | 130 175 204 | 45° | 250 | 0.2-2.2 | 200 | |||

| SHYC400 | 400 | 470 | ≥600 | 0-10 | 130 175 204 | 60° | 300 | 300 | ||||

| SHYC500 | 500 | 570 | ≥700 | 0-10 | 130 175 204 | 75° | 400 | 400 | ||||

| SHYC600 | 600 | 670 | ≥800 | 0-10 | 130 175 204 | 90° | 500 | |||||

| Note: can be designed and manufactured according to customer’s required size | ||||||||||||

Application

The magnetic chip conveyor uses the magnetic force of the strong magnetic field generated by the permanent magnet material to adsorb the chips on the working magnetic plate of the chip conveyor, or remove the granular, powdery and iron with a length of ≤150 mm in oil and emulsion. The chips are adsorbed and separated, and transported to the designated chip removal location or chip collection box. It can handle powdery, granular and iron scraps and non-rolled scraps with a length of less than 100 mm, or separate the scraps in oil and emulsion, and transport them to the designated chip removal box.

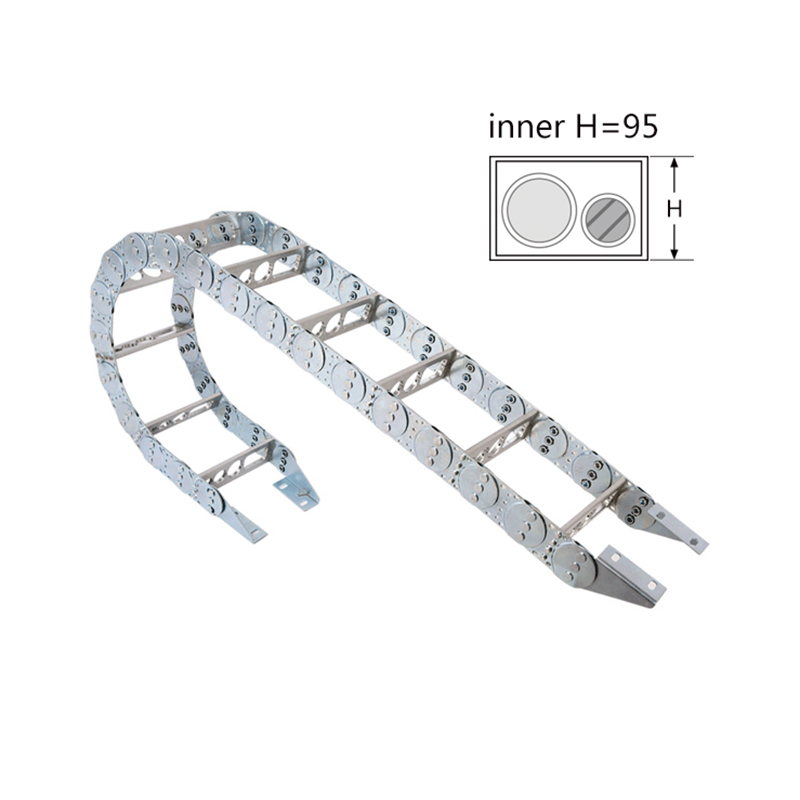

Product detail pictures:

Related Product Guide:

We follow our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We aim to create much more worth for our buyers with our abundant resources, highly developed machinery, experienced workers and great providers for Good quality Belt Chip Conveyor – Magnetic Type Chip Conveyor Equipment – JINAO , The product will supply to all over the world, such as: Pretoria, Ethiopia, Sydney, Our company has already have pass the ISO standard and we are fully respect our customer 's patents and copyrights. If the customer provides their own designs, We will guarantee that they will be the only one can have that products. We hoping that with our good products can bring our customers a great fortune.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!