Manufacturer for Auger Type Chip Conveyor - Magnetic Type Chip Conveyor Equipment – JINAO

Manufacturer for Auger Type Chip Conveyor - Magnetic Type Chip Conveyor Equipment – JINAO Detail:

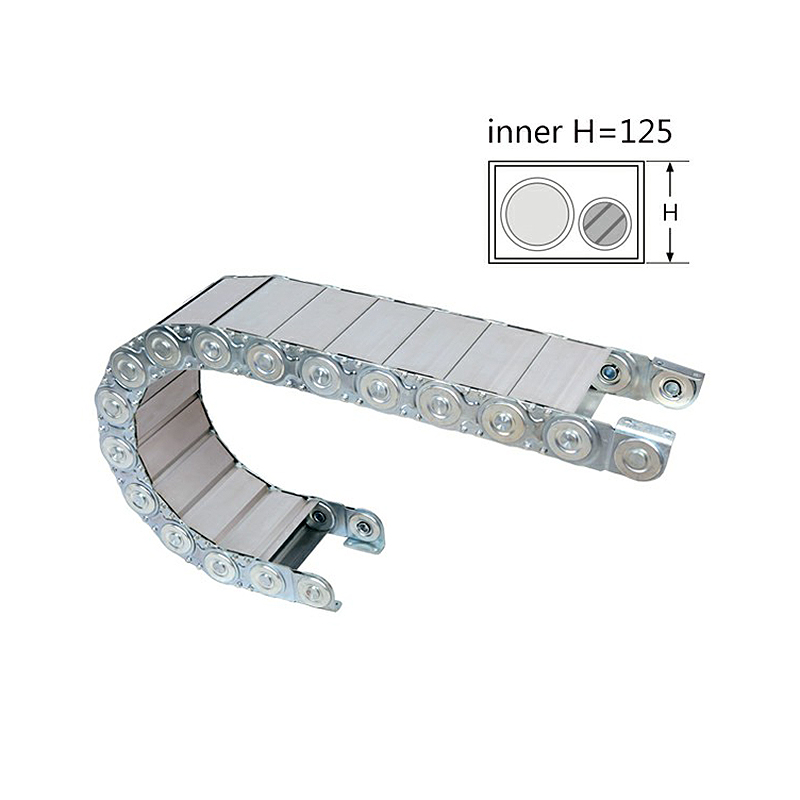

Magnetic chip conveyor utilizes the strong magnetic effect generated by the permanent magnet material to separate the powdery, granular and iron chips having a length of less than 100 mm, the debris in the cooling medium, and adsorbed on the working surface of the chip discharging machine. Delivered to the designated station. The machine can be widely used in CNC machining machines, combined machine tools, machining centers and other mechanical processing equipment and production lines for iron filings, and can be used for dry and warm processing of iron filings.

The device adopts a closed structure, uniform chip discharge, stable operation, low noise, and can be used for transportation and lifting of iron parts, and can be used as a primary filter in combination with a purifying device.

The Main Technical Parameters

| Style | Working width B | B1 | B2 | H(m) | H1 | H2 | H3/L1 | L(m) | a | kg/h | kw | l/min |

| SHYC150 | 150 | 220 | ≥300 | 0-3 | 130 175 204 | H1+≥30 (hypotenuse) | User-defined | 0.6-10 | 100 | 0.2-0.75 | 25 | |

| SHYC200 | 200 | 270 | ≥350 | 0-5 | 130 175 204 | 0.6-30 | 0° | 150 | 0.2-1.5 | 50 | ||

| SHYC250 | 250 | 320 | ≥400 | 0-10 | 130 175 204 | 30° | 200 | 0.2-1.5 | 100 | |||

| SHYC320 | 320 | 390 | ≥500 | 0-10 | 130 175 204 | 45° | 250 | 0.2-2.2 | 200 | |||

| SHYC400 | 400 | 470 | ≥600 | 0-10 | 130 175 204 | 60° | 300 | 300 | ||||

| SHYC500 | 500 | 570 | ≥700 | 0-10 | 130 175 204 | 75° | 400 | 400 | ||||

| SHYC600 | 600 | 670 | ≥800 | 0-10 | 130 175 204 | 90° | 500 | |||||

| Note: can be designed and manufactured according to customer’s required size | ||||||||||||

Application

The magnetic chip conveyor uses the magnetic force of the strong magnetic field generated by the permanent magnet material to adsorb the chips on the working magnetic plate of the chip conveyor, or remove the granular, powdery and iron with a length of ≤150 mm in oil and emulsion. The chips are adsorbed and separated, and transported to the designated chip removal location or chip collection box. It can handle powdery, granular and iron scraps and non-rolled scraps with a length of less than 100 mm, or separate the scraps in oil and emulsion, and transport them to the designated chip removal box.

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Manufacturer for Auger Type Chip Conveyor - Magnetic Type Chip Conveyor Equipment – JINAO , The product will supply to all over the world, such as: Borussia Dortmund, Czech republic, Colombia, With the superior and exceptional service, we are well developed along with our customers. Expertise and know-how ensure that we are always enjoying the trust from our customers in our business activities. "Quality", "honesty" and "service" is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!