The Importance of Efficient Chip Conveyor in CNC Machining

Learn about chip conveyors

Chip conveyors are specialized systems designed to remove chips from the machining area. They play a vital role in maintaining a clean and efficient workspace, which is essential for optimal machining performance. By quickly removing chips, these chip conveyors help prevent tool damage, reduce downtime, and improve overall productivity.

CNC Chip Conveyor: A Key Component

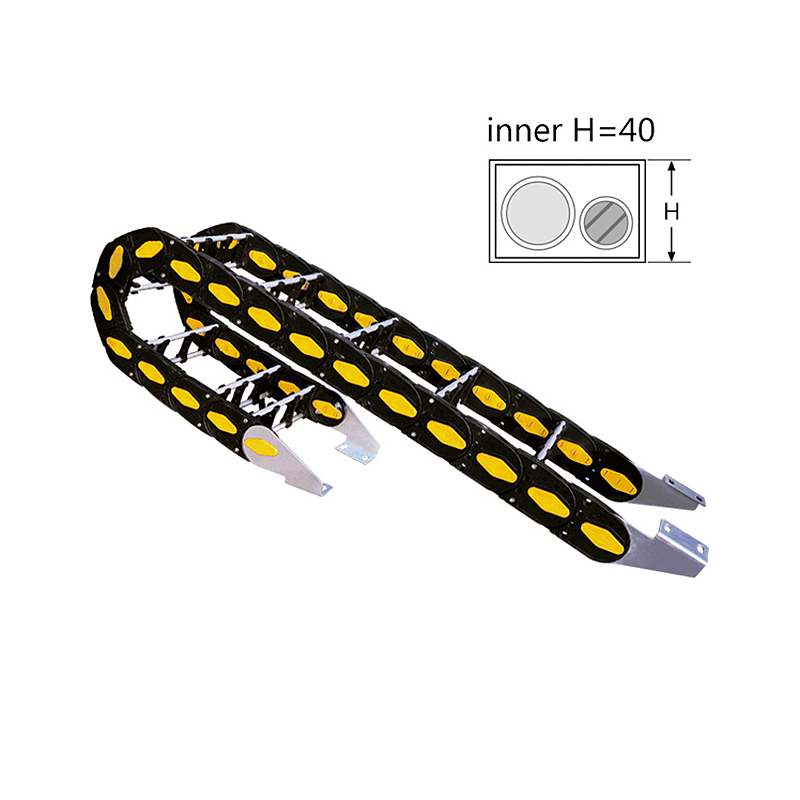

CNC chip conveyors are designed specifically for use with CNC machine tools. These chip conveyors are specifically designed to handle the unique challenges posed by the chips generated during CNC operations. They are available in a variety of designs, including hinged belt conveyors, magnetic conveyors, and spiral conveyors, each tailored for different types of materials and chip sizes.

A key advantage of CNC chip conveyors is their ability to handle a wide range of chip types, from small, fine particles to larger, heavier chips. This versatility makes them an essential component of any CNC machining system. Furthermore, many CNC chip conveyors offer features like adjustable speed and automatic control, allowing for seamless integration into existing machining processes.

Chamber conveyors: an alternative solution

While CNC chip conveyors are widely used, scraper-type chip conveyors also offer a viable solution for chip removal. Scraper-type chip conveyors utilize a series of scrapers or blades to collect and transport chips away from the machining area. This design is particularly effective for handling larger chips and can be used in a variety of industrial applications beyond CNC machining.

One of the main advantages of a scraper conveyor is its ability to operate in tight spaces. Its compact design allows it to fit into areas that are inaccessible to conventional conveyors. Furthermore, scraper conveyors have fewer moving parts than other types of conveyors, making them generally easier to maintain.

The impact of efficient chip removal on productivity

The importance of efficient chip evacuation cannot be overstated. Chip accumulation hinders the machining process and increases wear on both tools and machines. This not only increases maintenance costs but can also lead to costly production delays.

By investing in a high-quality chip conveyor, manufacturers can significantly improve operational efficiency. A well-designed chip conveyor system ensures that chips are continuously and effectively removed from the machining area, enabling uninterrupted production. This, in turn, improves product quality, reduces waste, and ultimately increases profitability.

In summary

In summary, chip conveyors (including CNC chip conveyors and chain conveyors) are an essential component of any CNC machining operation. They play a crucial role in maintaining a clean and efficient workspace, which is essential for optimal machining performance. By understanding the importance of these systems and investing in the right conveyor type for specific needs, manufacturers can increase productivity, reduce downtime, and improve overall operational efficiency. As the manufacturing industry continues to evolve, the role of chip conveyors in ensuring the success of CNC machining processes will only become increasingly important.