TL180 Steel Machine Tool Drag Chain

Our vast line up of standards will allow you to select the optimum cable carrier or hose carrier to suit your specific needs. Link heights from 2” for lighter duty applications through 14” for larger industrial type applications are available, as well as a huge array of bending radii and widths. Custom designs are a specialty. Cable and hose carriers are manufactured from 80,000 psi hi-tensile strength steel links with #12 gauge and #10 gauge link plates being the standard.

Each articulating joint consists of a hardened link pin with retaining ring or with hardened shoulder bolts and nylon locking nuts for those more rigorous applications. All parts are zinc plated with a yellow trivalent chromate dip for added corrosion resistance. Other materials of construction such as aluminum, stainless steel and Nylon are available.

We also offer a line of Mill Duty Cable carrier that are used in rugged applications and environments such as steel mills. They offer a box beam type carrier for maximum strength and stability. Spring loaded rods offer the customer easy access to cables and hoses. They also eliminate the concern of fitting sizes that must pass through the (fixed) compartment opening on a box beam style carrier. Hardened shoulder bolts and lock nuts are recommended for use in rugged environments. Cable drag chains is manufactured so that pieces or sections can be removed or replaced in the field.

Featuring

● Center pivot design for minimal cable and hose wear

● Wide variety of standard carrier designs

● Available in any radius or width

● Custom designs available to optimize your system

● Superior finish and corrosion resistance

● No pinch points

● Any width sections are available

● Short lead times

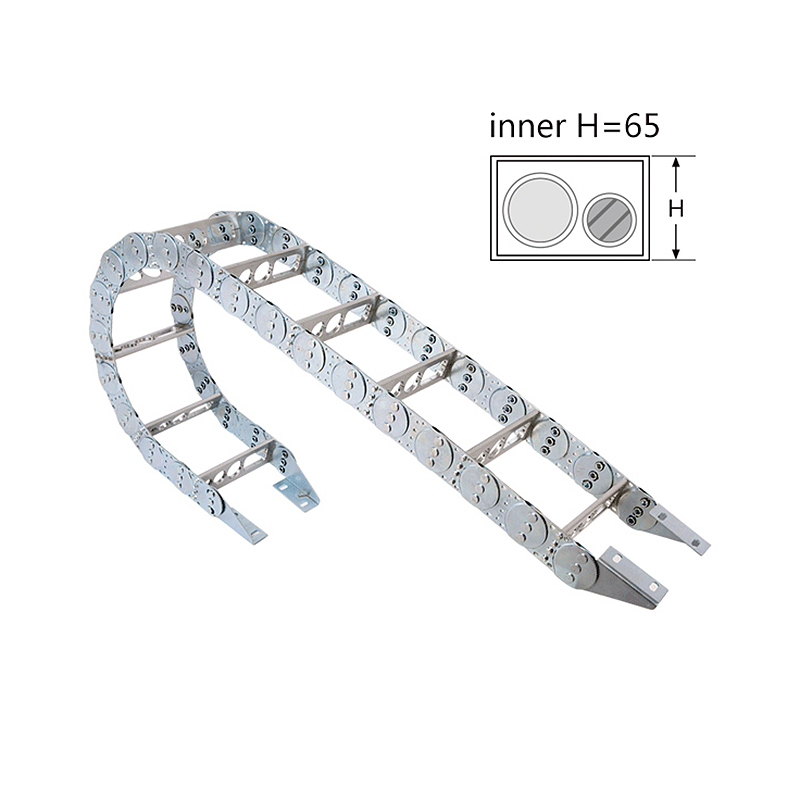

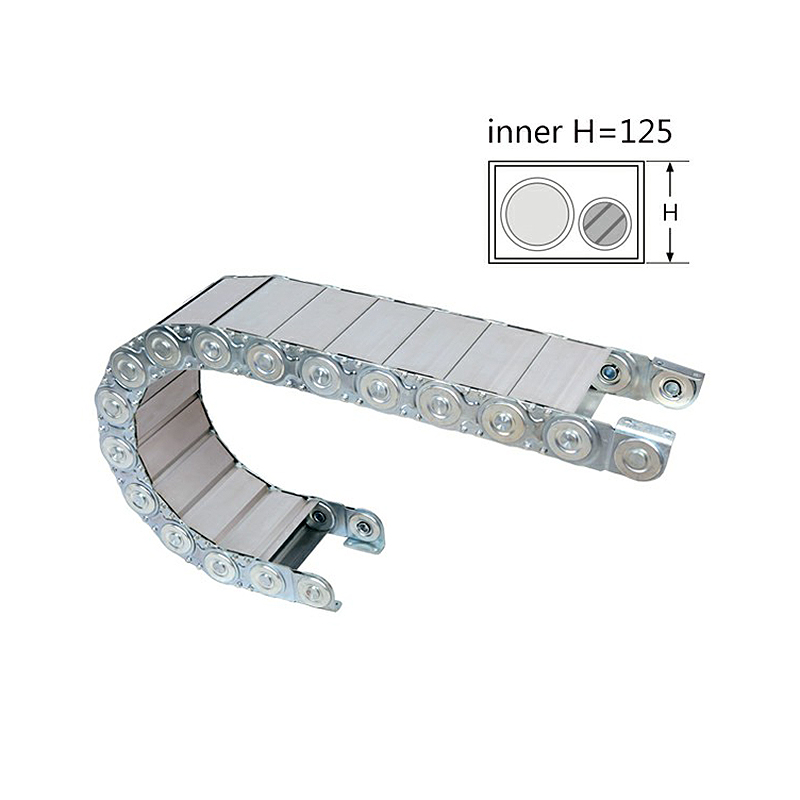

Model Table

| Type | TL65 | TL95 | TL125 | TL180 | TL225 |

| Pitch | 65 | 95 | 125 | 180 | 225 |

| Bending radius(R) | 75. 90. 115. 125. 145. 185 | 115. 145. 200. 250. 300 | 200. 250.300. 350. 470. 500. 575. 700. 750 | 250. 300. 350. 450. 490. 600. 650 | 350. 450. 600. 750 |

| Min/max Width | 70-350 | 120-450 | 120-550 | 200-650 | 250-1000 |

| Inner H | 44 | 70 | 96 | 144 | 200 |

| Length L | Customized by the user | ||||

| Max bore of support plate | 35 | 55 | 75 | 110 | 140 |

| Rectangular hole | 26 | 45 | 72 | ||

Structure Diagram